APPLICATION CENTER

Elevator & Escalator

Modern elevators are mainly composed of traction machines (winches), guide rails, counterweight devices, safety devices (such as speed limiters, safety gears and buffers, etc.), signal control systems, cars and hall doors...etc. Elevator steel has specific requirements for strength and corrosion resistance. At the same time, as an important part of modern buildings, the appearance, fire protection, and environmental protection of elevators are all important considerations.

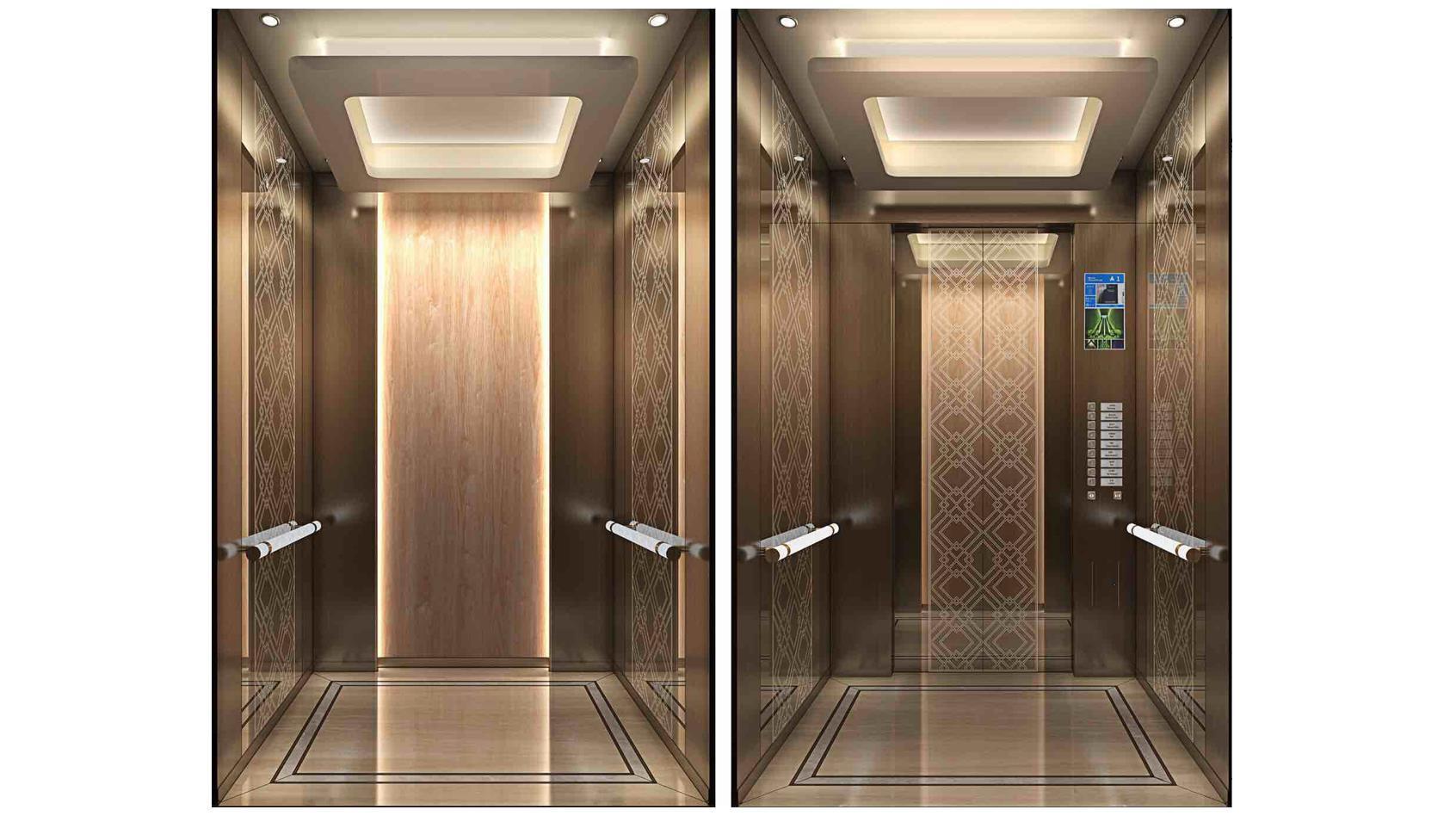

Stainless steel has the advantages of excellent strength, corrosion resistance, beauty and environmental protection, and has become one of the important materials for making elevators. In elevator/lift, stainless steel is mainly used in car decoration, ceiling, car door and hall door, door cover, floor display, control panel and handrail, etc.; in escalator, stainless steel is mainly used in escalator Skirts and inner and outer cover plates, steps, entrance and exit end cover plates, and escalator outer decoration packages.

The grades of stainless steel used in elevators are mainly concentrated in 304, 439, 443 and 316L. Among them, 304 stainless steel is used the most. 304's excellent corrosion resistance and mechanical properties make it the first choice for elevator companies. 316 stainless steel is mainly used in seaside, high corrosion occasions and heavy-duty escalators.

430 stainless steel is also widely used in the elevator industry. Its relatively low price is the key to attracting elevator companies. 430 stainless steel is used for general occasions and steps. At present, major steel plants have mass production of 430. Its sufficient supply and stability The quality is also one of the factors for the selection of elevator companies. Among them, Baoxin and Taigang's 430 cold-rolled materials have a better reputation in the elevator industry. 443 can partially replace 304 stainless steel under certain specific circumstances.

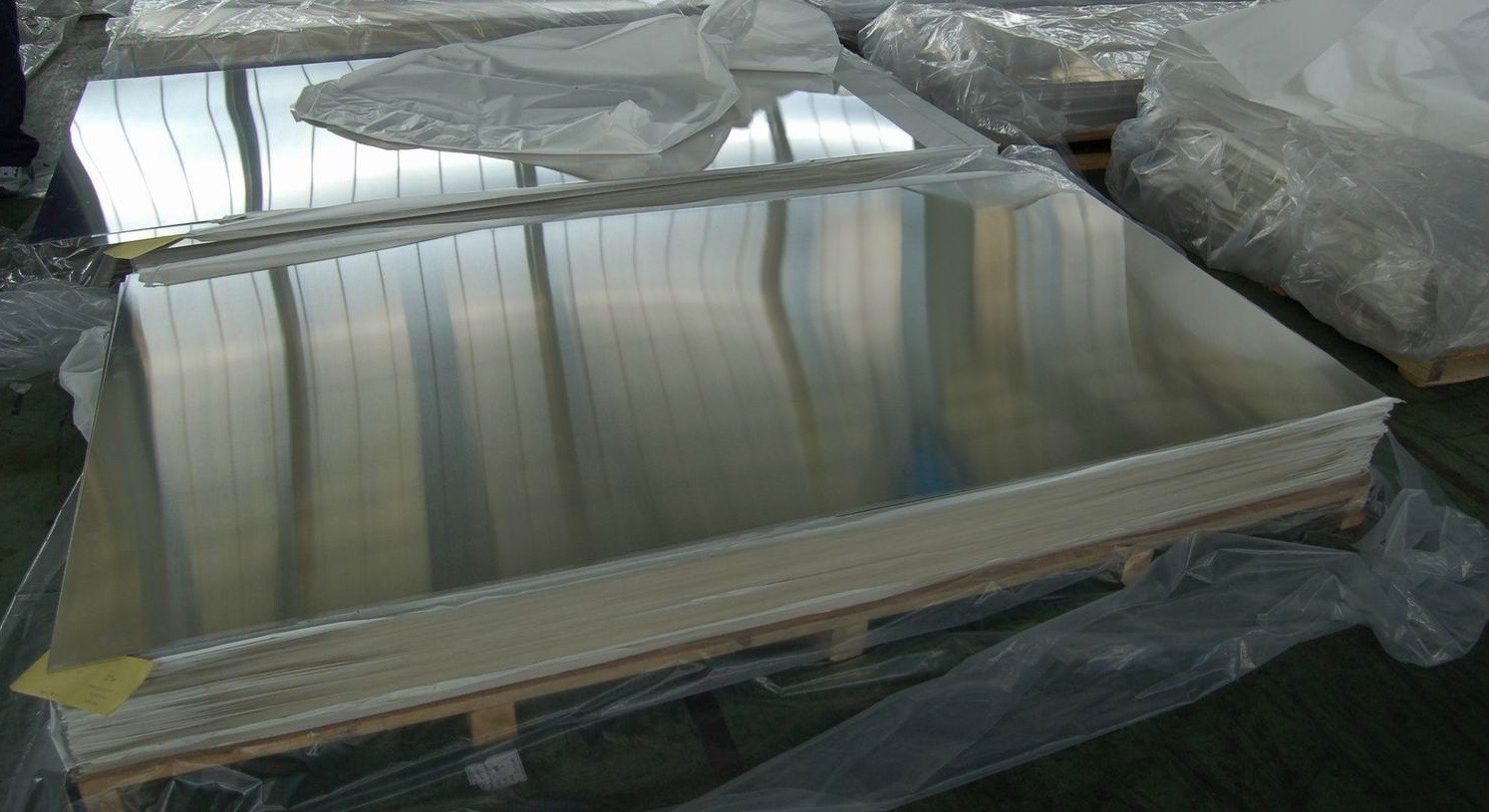

The thickness of elevator stainless steel products mainly adopts 0.5~3.0mm, of which products with thicknesses of 0.7mm, 0.8mm, 1.2mm, 1.5mm are mainly used for door panels, car panels, escalator side panels, etc.; 0.5mm, 0.6mm product thicknesses are mainly used For escalator steps; 2.0mm and 3.0mm thickness are mainly used for elevator lifting button substrates.

1. Stainless

steel mirror panel The manufacturing principle of the stainless steel mirror panel is to mechanically polish the surface of the original stainless steel plate with a grinding fluid to make the surface more flat and the brightness can be as clear as a mirror. It can be divided into two parts: polishing and light emitting. Grinding is divided into three processes: rough grinding, semi-finishing grinding, and fine grinding. The light is divided into two processes: waxing and bright. The whole process can be summarized as rough grinding → semi-finishing grinding → fine grinding → waxing → bright

⑴ Coarse grinding. Choose abrasives with a smaller material number, generally 600# abrasive belt, to grind the surface of the plate in a straight line to remove impurities and rough places on the surface of the plate.

⑵Semi-precision grinding. Use 800# abrasive belt to polish the surface according to the first step method, which is mainly to further finely polish the impressions produced after rough grinding to achieve no impressions on the surface and basically brighten.

⑶ Fine grinding. Continue to polish with 1000# abrasive belt, mainly to correct and grind the small lines on the surface of the plate, and the surface of the plate will be further brightened, which is basically close to the mirror effect.

⑷ Waxing. The wool wheel and green wax are selected, and the green wax is glued on the wool wheel. The surface of the sheet is mirror-polished by the above-mentioned polishing method. The main purpose of this process is to complete the mirror-polishing of the sheet, rather than further grinding.

⑸ Bright. This process is the last process. A clean cotton cloth wheel is used to rub the surface of the plate after the mirror surface. The purpose is to clean and polish the surface of the plate.

2. Stainless steel checkered plate The

stainless steel checkered plate is particularly widely used in the elevator industry, especially in the application of elevator decoration. Not only can it meet the elevator's demand for plates in terms of material and size, but also in terms of decoration and beautification. Own unique landscaping value.

The stainless steel checkered plate is embossed on the stainless steel plate through mechanical equipment to make the surface of the plate appear uneven. Main advantages: durable, durable, durable, and decorative.

The width is 680, 730, 750, 1219mm, and the thickness is 0.5mm~1.2mm. Patterns include checkered pattern/diamond pattern/coarse hemp pattern/ice pattern/ellipse pattern/tile pattern/twill pattern/rice grain board/millet grain board/bead pattern board/cube pattern/woven bamboo pattern/free pattern/butterfly flower/ Stone grain.

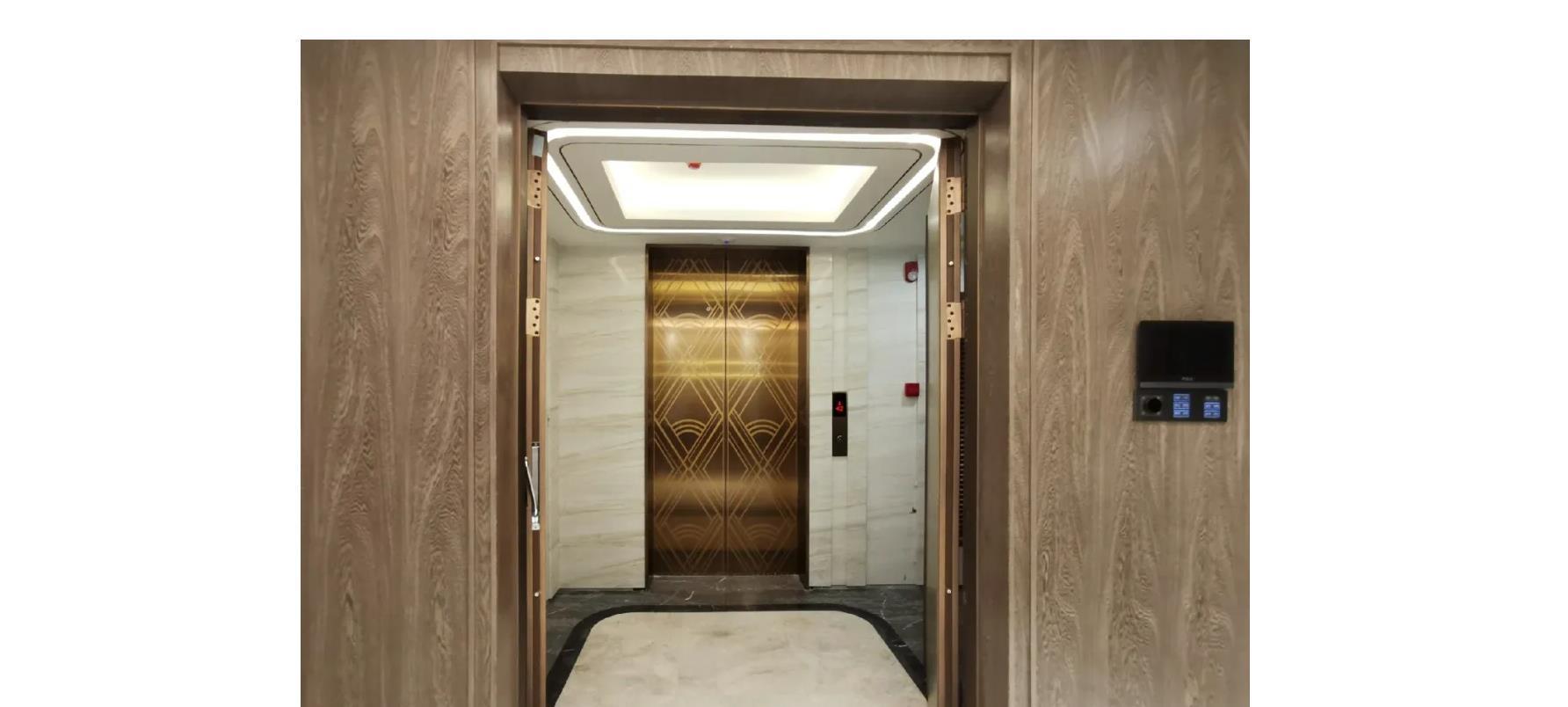

3. Stainless steel etching plate The

stainless steel etching plate is chemically corroded on the surface of stainless steel to form various patterns. The 8K mirror panel, wire drawing board, and sandblasting board are used as the bottom plate. After etching, the surface of the object is further processed to reflect the sense of hierarchy. The etching plate can be processed with various complicated processes such as partial patterning, drawing, gold embedding, partial titanium gold, etc., to achieve the effect of bright and dark patterns and brilliant colors.

Stainless steel etching plate is mainly used on the decorative plate of elevator hall door. The surface is generally mirror-etched, partially brushed, and partially chaotic. The color of stainless steel pattern plate is generally golden yellow and rose gold. The etching pattern can be customized, and most of the patterns are patchwork type. The material is generally 304.

The second is to be applied to the decorative panel of the elevator car. The etching pattern is generally symmetrical. It is mostly used with hall door decorative panels.

Personalized Information Service!

Drop your email to get market insights, product specs and latest rate info.

Copyright©2014-2025. BISCO. All Rights Reserved.

anything

Sitemap | Contact Us | Privacy Statement | Terms of Use | Online Security