APPLICATION CENTER

Automobile

To make a car, we need many different materials such as steel materials, non-ferrous metals, composite materials, glass, rubber, etc. Among them, steel materials account for 65%-85% of the car's own weight in different models, whether it is the car shell or the car’s own weight. In its heart, the figure of steel material can be seen everywhere.

Automobile steel is mainly divided into two categories: one is automobile body steel, which constitutes the outer shell and skeleton of the automobile; the other is automobile alloy structural steel, which is the core of automobile engine, transmission system, suspension system, etc. Material. Next, we will give you a detailed introduction.

1. Steel for automobile body

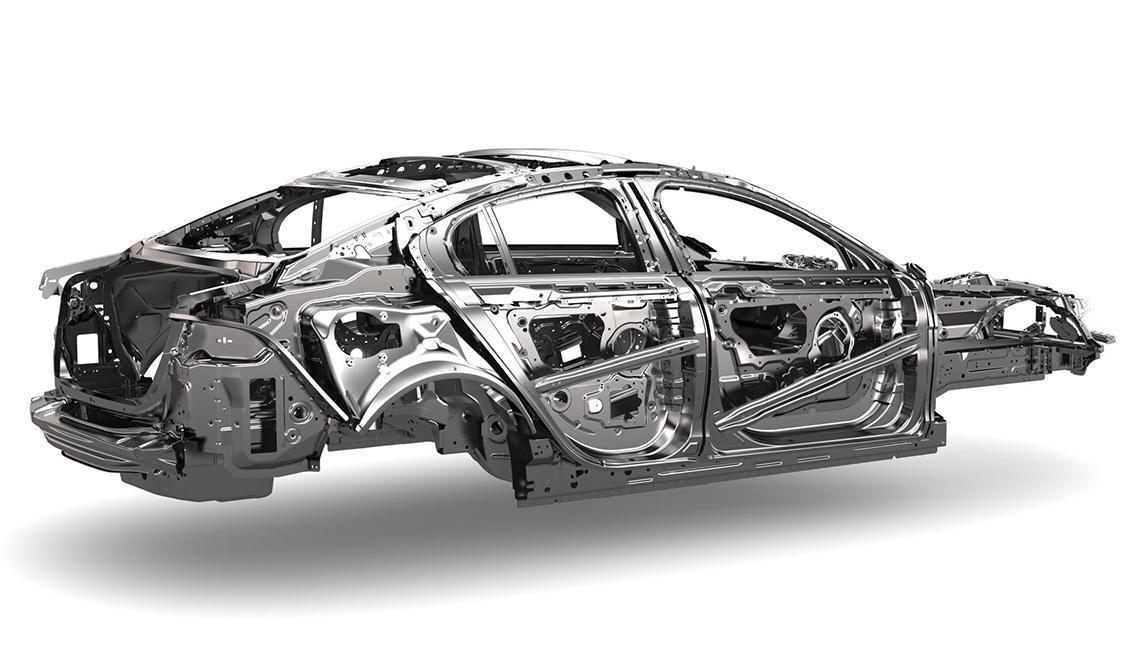

Let's first look at steel for automobile body. Load-bearing body, the whole body is one body, steel constitutes his skeleton, and the engine, transmission system, front and rear suspension and other components are assembled on this skeleton. The figure below is the body structure diagram. We analyze one by one from the outside to the inside.

1. Steel for outer panel of

automobile body The steel for outer panel of automobile body is mainly used to manufacture front, rear, left and right door outer panels, engine hood outer panels, trunk lid outer panels and other parts. It should have good formability, corrosion resistance, dent resistance and good weldability. In order to improve the dent resistance, baking hardened steel, high-strength IF steel and high-formability cold-rolled annealed dual-phase steel (such as DP450) are often used for automobile body outer panels to meet anti-corrosion requirements. Coated sheets are mostly hot-dip galvanized sheets, hot-dip galvanized iron sheets, electro-galvanized sheets, electro-galvanized-nickel sheets, etc.

2. The steel for the inner panel of the car body

Through the outer panel of the car, we can see that the shape of the parts of the inner panel of the car body is more complicated. This requires the steel for the inner panel of the car body to have higher formability and deep drawing performance. Therefore, the inner panel of the car body IF steel with excellent stamping formability and deep drawing performance is mostly used, and a small amount of high-strength IF steel is used, and the coating requirements are similar to those of the outer plate.

3. Car body structural parts

Going further, we can see the car body structural parts. It is closely related to the safety and lightweight of automobiles. Therefore, the selection of materials requires both high strength and high plasticity. Advanced high-strength steel (AHSS) is mostly used in car body structural parts due to its strong plastic bonding, good crash characteristics and higher fatigue life. For example, it has been widely used in key parts such as front and rear bumper frames and A-pillars and B-pillars. In the event of an impact, especially in frontal and side impacts, it can effectively reduce the deformation of the cockpit and protect the safety of drivers and passengers. . Advanced automotive high-strength includes dual-phase steel, martensitic steel, phase transformation induced plasticity steel, duplex steel, and quenched ductile steel.

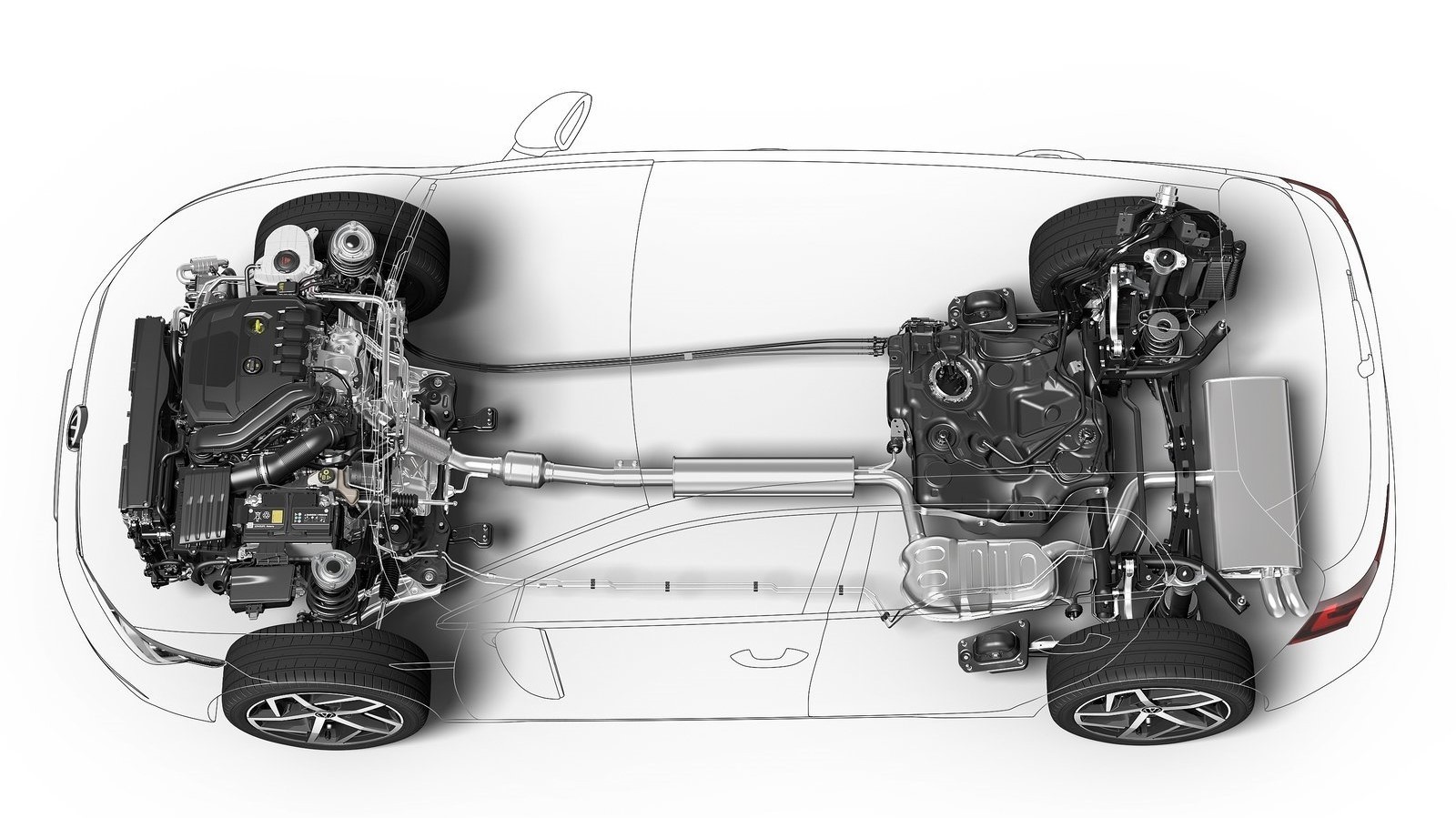

2. Alloy Structural Steel

for Automobiles Knowing the steel used for the outer shell and skeleton of automobiles, let's continue to understand the alloy structural steels for automobile that are hidden inside the car body. Mainly include: quenched and tempered steel and non-quenched and tempered steel for shafts, steel for gears, steel for various springs, and steel for various high-strength standard parts.

1. Quenched and tempered steel and non-quenched and tempered steel

for axles Various axles play an important role in automobiles. As long as cars start to run, they are under great stress. The front bearing is subjected to bending fatigue stress, the curved bearing is subjected to bending and torsion composite stress, the transmission bearing is subjected to torsional fatigue stress, and the connecting rod is subjected to asymmetric tensile and compressive stress... In order to make them work healthily and safely, quenched and tempered steel for shafts usually contains Certain alloying elements not only ensure hardenability (a capacity to ensure that the strength of each part of the part's section meets the requirements of the part), but also improve the impact toughness. At present, quenched and tempered steels for crankshafts are 40Cr, 42CrMo, etc., automobile half shafts are commonly used in S45C, SCM4, SCM6, SAE1045, etc., and automobile connecting rods are mostly quenched and tempered steels such as 40Cr and S48C. Non-quenched and tempered steels such as 12Mn2VBS and 35MnVN have also been widely used in steering knuckles and engine connecting rods.

2. Gear steel

gear is also an important power transmission component in automobiles. The performance requirements of gear steel are: high crush resistance and pitting corrosion resistance; good impact resistance and bending ability; suitable hardenability And hardened layer depth and core hardness; good process performance and machinability; and deformation and dimensional stability. Gear steel includes SCM420, SCM822 and other Cr-Mo series, Cr-Ni-Mo series and Ni-Mo series.

3. Spring steel

springs are used in automobiles with a large amount and variety. It is a basic structural part. The main use is spring steel and valve spring steel for suspension. In light or heavy trucks, the amount of spring suspension is generally 100- 500kg. The performance requirements of spring steel are: high elastic limit and relaxation resistance, good hardenability and suitable hardenability, high fracture toughness and strain fatigue life, good metallurgical process performance and formability, certain wear resistance and Corrosion resistance. At present, the steels for suspension springs mainly include: Si-Mn series, Mn-Cr series, Cr-V series, Mn-Cr-B, etc.

4. Various types of steel for high-strength standard parts.

In recent years, high-strength standard parts have gradually increased in automotive applications. Steel for riveting screws is one of them. It requires good process performance, machinability, strength performance, and fatigue performance. And the delayed fracture ability under high strength.

Commonly used brands of passenger

①HC260B, B180H1, JSC340H, SPFC340H,

②HC700/980DP, HC820/1180DP, MS1500T/1200Y,

③HC380/590TR, CR780T/440Y-TR,

④JSC270C, DC01, DC03, DC51D+Z,

⑤HC600/980QP, S700MC et

⑥HC220P2, HC260LA, JSC 440Y, B280VK , SPFC780 other

⑦DC51D + AS, DC53D + MA, 409L, 439 , etc.

⑧40Gr, GGr15,60Si2MnA, 50GrVA other

⑨B380CL, SPFH540 etc.

Commonly used brands of trucks

①SPA-C, HC400/780DP, S350GD+Z,

②QStE500TM, 510L, 700L, SAPH440, SPFH590, etc.

Personalized Information Service!

Drop your email to get market insights, product specs and latest rate info.

Copyright©2014-2025. BISCO. All Rights Reserved.

anything

Sitemap | Contact Us | Privacy Statement | Terms of Use | Online Security