APPLICATION CENTER

Machinery

A machine is a combination of human-made physical components, with a certain relative movement between each part. It is a tool device that can help people reduce the difficulty of work or save effort. Complex machinery is composed of two or more types of simple machinery. Complex machinery is usually called a machine.

There are many types of machinery, which can be divided into agricultural machinery, mining machinery, construction machinery, petrochemical general machinery, electrical machinery, machine tools, instrumentation, basic machinery, packaging machinery, environmental protection machinery, etc. according to the industries served.

Steel for machinery manufacturing, structural steel used to manufacture mechanical parts that bear load or transmit work and force, also known as machine structural steel. According to the purpose, it can be divided into quenched and tempered steel, surface hardened steel (including carburized steel, nitrided steel, low hardenability steel), free-cutting steel, spring steel and rolling bearing steel.

One. Quenched and tempered steel

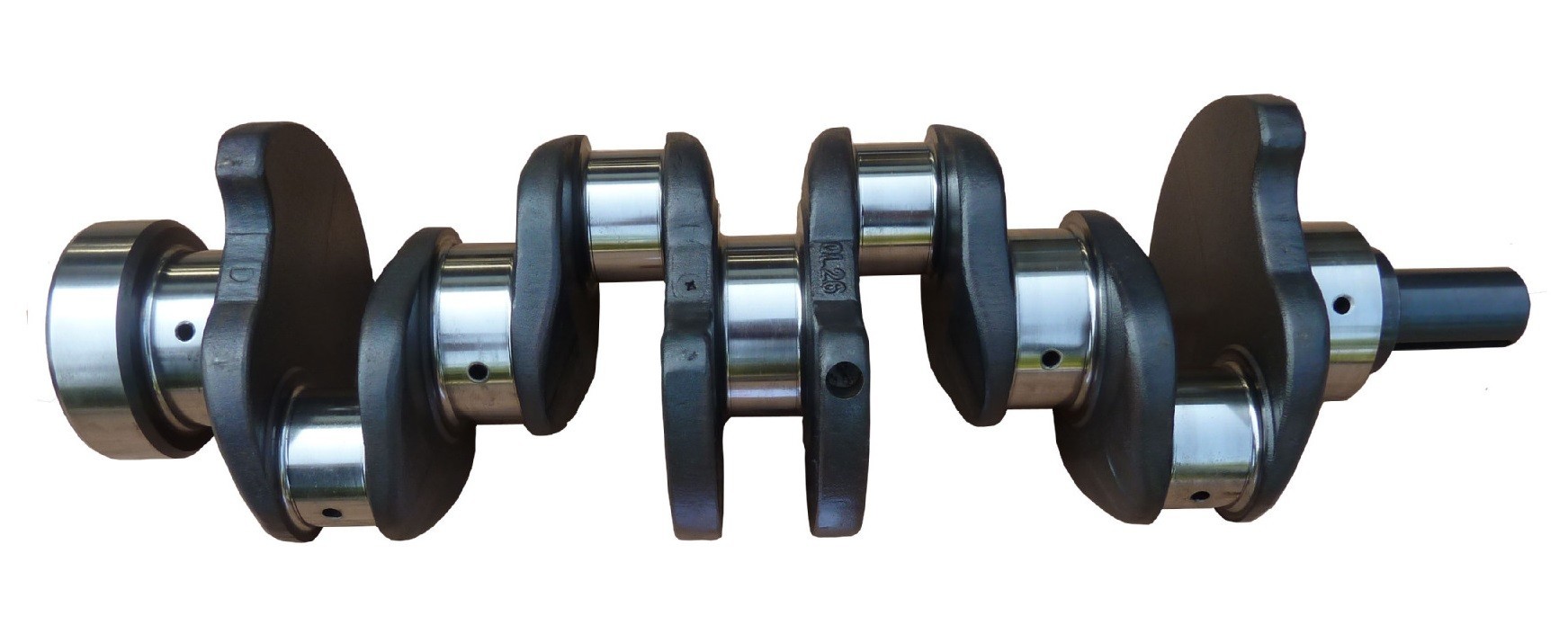

quenched and tempered steel ships before use and then tempered before quenching, to achieve the required strength and toughness. The carbon content of quenched and tempered carbon steel is 0.03 to 0.60%. Because of its low hardenability, it is only used to manufacture mechanical parts with small cross-sectional dimensions, simple shapes or low loads. Alloy quenched and tempered steel is based on carbon quenched and tempered steel by adding one or several alloying elements, and the total amount of added alloying elements is generally not more than 5%. Alloy quenched and tempered steel has good hardenability, can be hardened in oil, has small quenching deformation, and has better strength and toughness. Commonly used steel grades are 40Cr, 35CrMo, 40MnB, etc. For important parts with large cross-section size and high load, such as aero engine main shaft, crankshaft and connecting rod of high-speed diesel engine, main shaft of steam turbine and generator, and other steels with high content of alloying elements, such as 40CrNiMo, 18CrNiW, 25Cr2Ni4MoV, etc.

Two. Carburized steel

Carburized steel is used to manufacture parts that require hard and wear-resistant surfaces and strong and impact-resistant cores, such as chain pins, piston pins, gears, etc. The carburized steel has a low carbon content of 0.10 to 0.30% to ensure the core toughness of the parts. After carburizing treatment, a high-carbon and high-hardness wear-resistant layer can be formed on the surface. The more important parts can be alloy carburized steel. Commonly used steel grades are 20CrMnTi, 20CrMo, 20Cr, etc.

Three. Nitrided steel

Nitrided steel contains alloying elements that have a strong affinity for nitrogen, such as aluminum, chromium, molybdenum, vanadium, etc., to facilitate the infiltration of nitrogen. The nitriding layer is harder, more wear-resistant and corrosion-resistant than the carburized layer, but the nitriding layer is thinner. After nitriding, the deformation of parts is small, and it is commonly used to manufacture precision parts with small allowable wear, such as grinding machine spindles, plunger pairs, precision gears, valve stems, etc. The commonly used steel grade is 38CrMoAl.

Four. Low hardenability steel

Low hardenability steel is a special carbon steel with low residual elements such as manganese and silicon. The central part of the parts made of this kind of steel is harder to harden during quenching than ordinary carbon structural steel. The hardened layer is basically evenly distributed along the surface contour of the part, while the central part maintains a softer and tougher matrix instead of infiltration. Carbon steel makes gears, bushings, etc., which can save time-consuming carburizing process and save energy. In order to properly match the toughness of the central part with the hardness of the surface, the carbon content is generally 0.50 to 0.70%.

Fives. Free-cutting steel Free-

cutting steel is the addition of one or more elements such as sulfur, lead, calcium, selenium, etc. to the steel to reduce cutting force. The added amount is generally only a few thousandths or less. Use the added element itself or add the element Combine with other elements in steel to form an inclusion that can reduce friction and promote chip breaking during the cutting process, so as to achieve the purpose of extending tool life, reducing cutting force, and improving surface roughness. Since the addition of sulfur will reduce the mechanical properties of steel, it is generally only used to manufacture light-loaded parts. Modern free-cutting steel is also widely used in the manufacture of auto parts due to improved performance.

Six. Spring steel

Spring steel has a high elastic limit, fatigue limit and yield ratio. Its main application is springs. Springs are widely used in various machinery and instruments. Their appearance can be divided into two categories: leaf springs and coil springs. The main function of the spring is shock absorption and energy storage. When the spring works, it produces great elastic deformation, absorbs impact energy, and eases the impact, such as buffer springs on automobiles and other vehicles; springs can also release the absorbed energy to enable other parts to complete certain actions, such as the air valve on the engine Springs, instrument springs, etc.

Seven. Bearing steel

Bearing steel has high and uniform hardness and wear resistance, as well as high elastic limit. Bearing steel has strict requirements on the uniformity of chemical composition, the content and distribution of non-metallic inclusions, and the distribution of carbides. It is one of the most stringent steel grades in all steel production. Bearing steel is a steel grade used to make rolling bearing balls, rollers and sleeves. It can also be used to make precision measuring tools, cold punching dies, machine tool screws, such as punching dies, measuring tools, taps, and precision parts for diesel oil pumps.

Personalized Information Service!

Drop your email to get market insights, product specs and latest rate info.

Copyright©2014-2025. BISCO. All Rights Reserved.

anything

Sitemap | Contact Us | Privacy Statement | Terms of Use | Online Security